Products

Products

solution and support

solution and support

contact

Contact

Kaihua's Stack Mould Technology Breaks Production Limits, Leading Smart Manufacturing Revolution in Injection Molding

TIME : 2025/5/29 13:57:35

Amid the wave of intelligent and high-efficiency transformation in the plastic mold industry, Kaihua Mold has successfully applied stack mould technology to both automotive mold manufacturing and household mold production. This breakthrough effectively overcomes the productivity limitations of traditional injection molding, delivering a cutting-edge solution that reduces costs while enhancing efficiency for manufacturers. Recognized as a "pioneering technology in plastic molds," this innovation is reshaping industry production models with its compelling advantages.

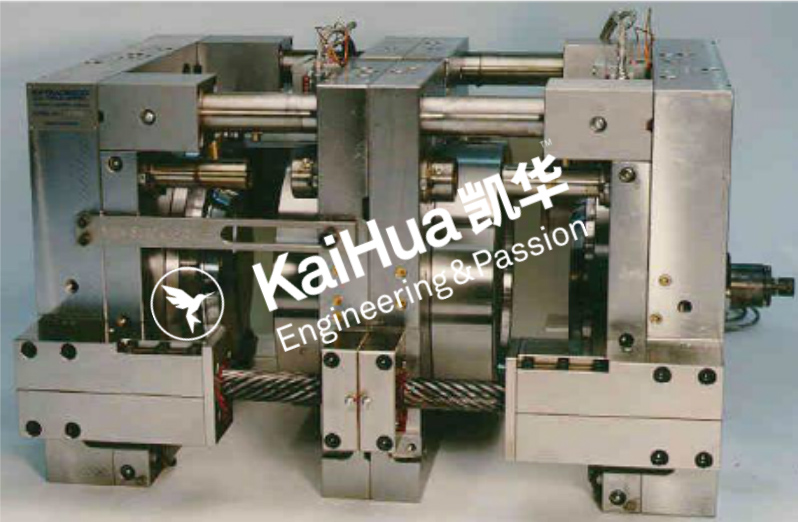

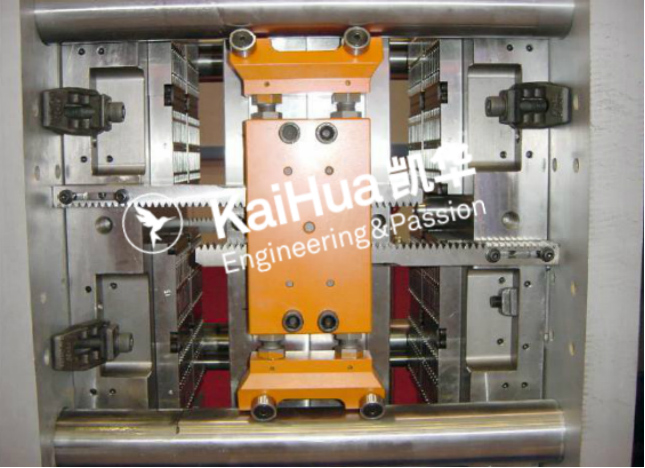

In conventional single-layer injection molding, machine shot capacity and mold opening stroke utilization rates have long remained stagnant at 20%-40%, resulting in significant equipment underutilization. Kaihua's stack mould technology revolutionizes this approach by innovatively distributing cavities across two or more tiers, integrating multiple mold functions through an overlapping configuration. Without requiring additional clamping force, this breakthrough enables a single injection molding machine operated by one technician to achieve multiplied output. Compared to standard molds, the stack mould system delivers a dramatic 90%-95% production surge with only a 10%-15% increase in clamping force - truly realizing the "small investment, big returns" principle in manufacturing optimization.

The value of Kaihua's stack mould technology extends far beyond productivity gains, delivering transformative benefits across the entire production chain. In mold manufacturing, Kaihua's proven process integrates multiple cavities into a single mold unit, significantly shortening lead times. On the production floor, the technology requires no additional equipment investment while effectively reducing costs associated with facility expansion and additional labor. Remarkably compatible with standard injection machines, these stack moulds achieve multiples of the output efficiency compared to single-layer systems. Beyond core productivity advantages, the technology offers material savings, enhanced automation compatibility, and improved product performance—particularly excelling in mass production of large flat components, shallow-cavity housings, and small thin-walled multi-cavity parts. This makes it an ideal cost-effective solution for automotive applications, where precision and volume production are paramount.

To ensure the stability and reliability of its stack moulds, Kaihua's R&D team conducted systematic breakthroughs targeting key technical challenges. The engineering team implemented precision calculations to meticulously control the sprue bushing length and mold opening stroke, eliminating any risk of sprue ejection after mold opening. Simultaneously, they optimized the plasticizing efficiency and injection rate of the injection machines to ensure uniform melt filling across all cavities. Addressing the industry-wide challenge of uneven melt pressure in multi-layer cavities, Kaihua pioneered innovative hot runner pressure-release technology. Through scientific cavity layout planning and strategic sprue bushing positioning, the team achieved synchronized, high-efficiency molding across all stacked levels.

Kaihua's stack mould technology has already been adopted at scale by multiple industry leaders, delivering measurable gains in production efficiency and product competitiveness. Moving forward, Kaihua will continue to advance its technological development, driving innovation to power high-quality growth across global manufacturing sectors.