Products

Products

solution and support

solution and support

contact

Contact

Stackable Plastic Pallets: A Logistics Space Revolution Driven by Injection Molding Technology

TIME : 2025/9/5 14:17:39

In the modern logistics system, stackable plastic pallets are quietly driving an efficiency revolution. This seemingly simple logistics carrier embodies the essence of injection molding technology and has become an indispensable infrastructure in the global supply chain. From raw materials to finished products, every link demonstrates the wisdom and innovation of modern manufacturing. As a professional force deeply engaged in the field of stackable plastic pallet molds, Kaihua Molds has injected key momentum into this logistics efficiency revolution with its rich manufacturing experience.

Precision Injection Molding: The Core Process of Pallet Manufacturing

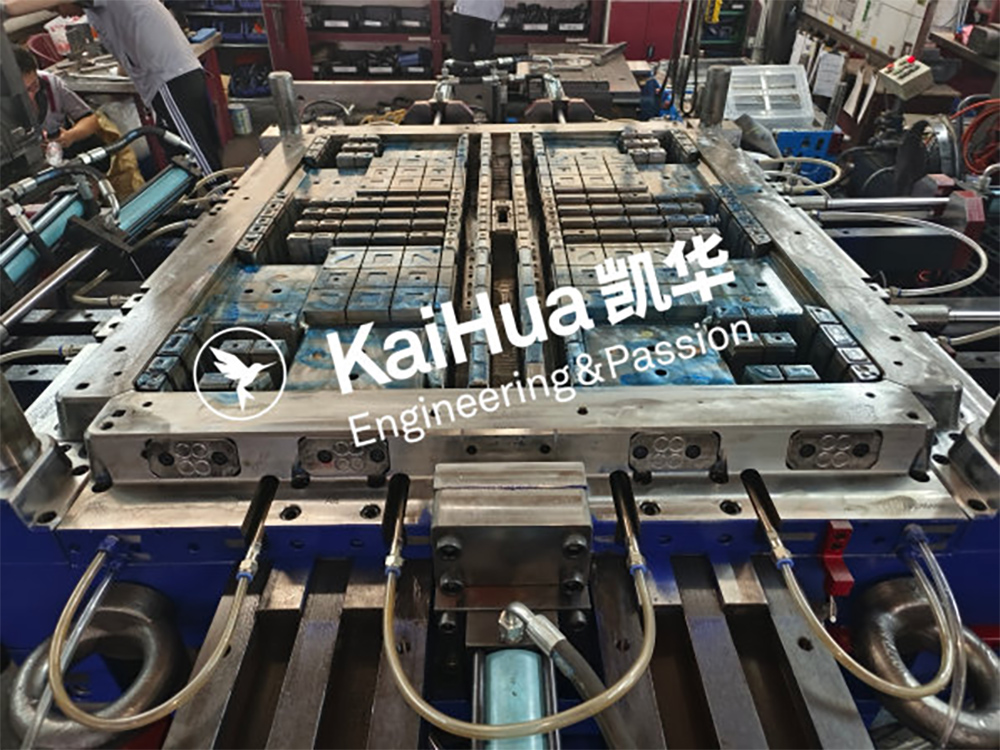

The production of stackable pallets is inseparable from precision injection molding technology. The injection molding process enables the one-time molding of complex structures, ensuring that each pallet has highly consistent dimensional accuracy and stable mechanical properties. The design quality of the mold directly determines the stacking accuracy, load-bearing capacity, and service life of the pallet.

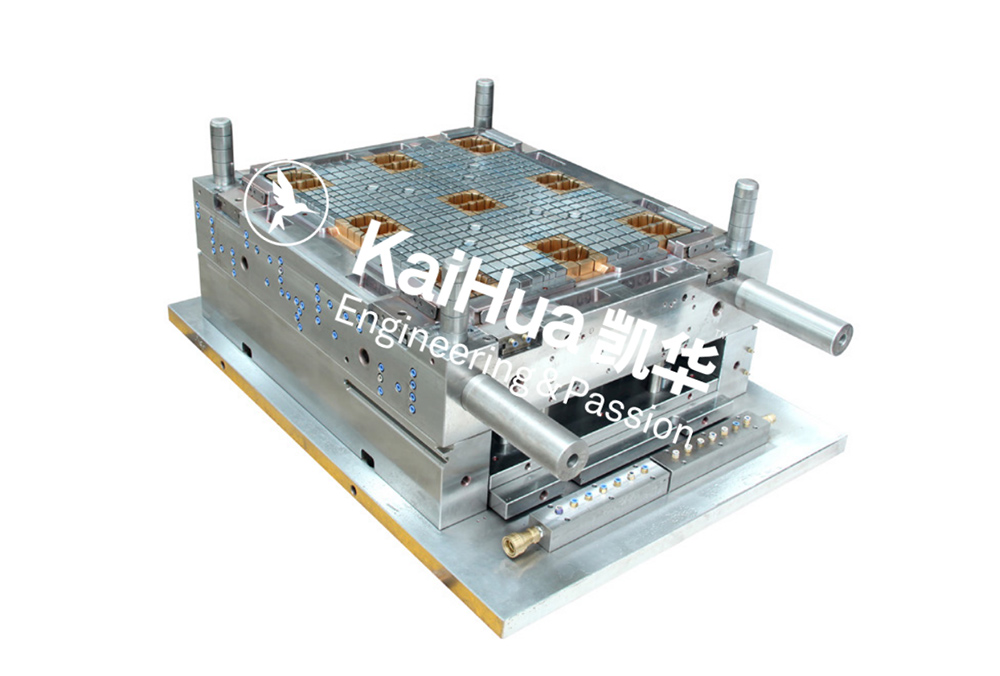

Kaihua Molds has accumulated profound experience in the manufacturing of stackable plastic pallet molds and maintains precise control over the core processes of pallet production. For the complex stacking buckle structure of pallets, Kaihua Molds skillfully applies multi-slide linkage mechanisms and angled ejector systems to ensure smooth and stable demolding every time. Even after millions of injection cycles, the mold precision remains undiminished. Meanwhile, Kaihua Molds is well aware of the importance of filling efficiency for large-sized pallets (e.g., 1200×1000mm). By optimizing the design of hot runner systems, it not only significantly reduces runner waste and improves injection efficiency but also achieves rapid and uniform filling of plastic melts, ensuring the molding quality of pallets from the source.

High-end injection molds have extremely high requirements for material wear resistance and processing precision, which are fully reflected in Kaihua Molds' products. High-wear-resistant mold steel is selected, combined with precision CNC machining technology, allowing the molds to withstand long-term high-intensity production while consistently ensuring the dimensional consistency of pallets, thus eliminating precision obstacles for customers' subsequent pallet stacking.

Perfect Collaboration Between Materials and Molds

Stackable plastic pallets mainly use two types of engineering plastics: high-density polyethylene (HDPE) and polypropylene (PP). The different properties of these two materials require corresponding mold design solutions. HDPE has a relatively high shrinkage rate, so the mold needs to be equipped with an efficient and uniform cooling system to prevent warping and deformation of the product. PP, on the other hand, requires more precise mold temperature control to optimize the crystallization process and obtain better product rigidity.

With a deep understanding of the properties of different materials, Kaihua Molds can provide customized mold solutions for customers: For HDPE pallets, Kaihua Molds accurately designs the layout of cooling water channels through CAE simulation analysis to ensure uniform and rapid cooling, effectively avoiding pallet warping. For PP materials, Kaihua Molds optimizes the mold temperature control system to precisely regulate the mold temperature, helping customers produce pallets with higher rigidity and durability.

In recent years, environmental protection requirements have promoted the application of recycled materials in pallet production, which has posed new challenges to mold wear resistance and venting systems. Kaihua Molds has laid out in advance: by upgrading the mold surface treatment process to enhance wear resistance and optimizing the design of venting systems, it effectively solves the problems of bubbles and impurities easily generated during recycled material injection. This helps customers practice environmental protection concepts without reducing the production quality of pallets, while saving raw material costs and expanding material options for customers.

Innovative Design Delivers Outstanding Performance

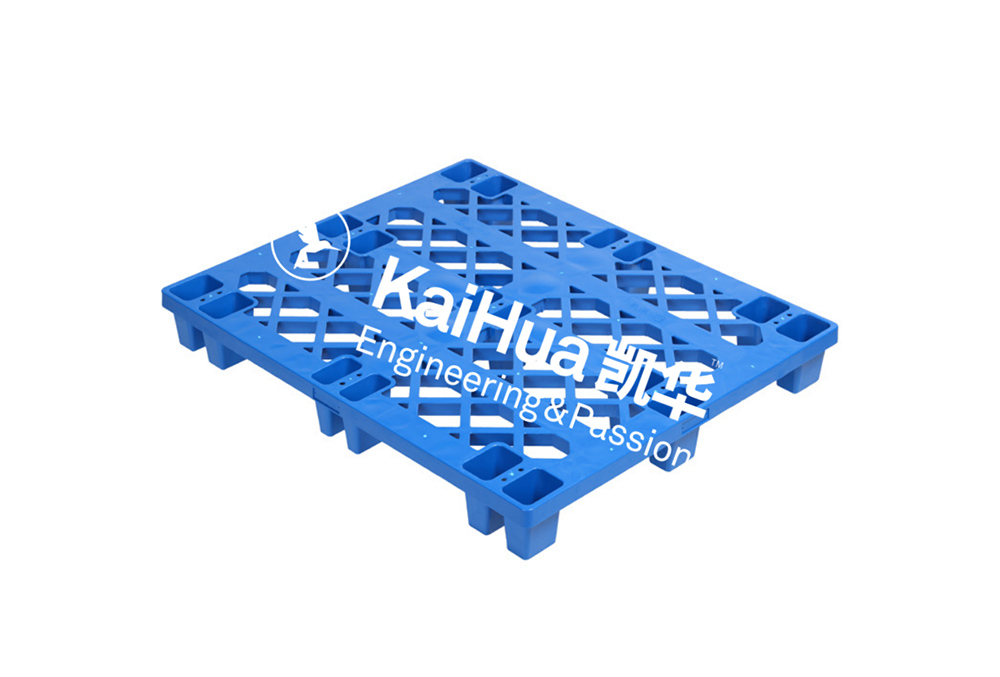

The design of stackable plastic pallets fully reflects the advantages of the injection molding process. The unique stacking buckle structure is realized through precision mold design, allowing empty pallets to nest tightly together, saving up to 80% of storage space. The crisscross reinforcing rib network on the back not only reduces weight but also significantly improves load-bearing capacity, enabling the pallet to withstand a maximum static load of 4 tons and a dynamic load of 1.5 tons.

The nine-leg grid design is another typical application of the injection molding process. This structure not only provides stable support but also ensures the balance and safety of the pallet when carrying goods. The grid-shaped surface design increases ventilation and drainage, preventing goods from being damaged by moisture—all of which benefit from precision mold processing technology. Kaihua Molds plays a key role in the implementation of innovative pallet designs: Whether it is the precise molding of stacking buckles or the stress optimization of reinforcing rib networks, Kaihua Molds can transform customers' pallet performance requirements into actual products through detailed mold structure design. For example, for pallets requiring high load-bearing capacity, Kaihua Molds optimizes the connection structure between reinforcing ribs and the pallet body to enhance overall load-bearing capacity; for customers with tight storage space, Kaihua Molds refines the precision of stacking buckles to ensure tighter pallet nesting and further improve space utilization.

Wide Applications and Future Development

Stackable plastic pallets have been widely used in many industries such as food and beverage, chemicals, pharmaceuticals, and automobiles. In the food and beverage industry, their compliance with international hygiene standards and easy cleaning properties make them the largest application market. The pharmaceutical industry values their easy cleaning and disinfection as well as high-temperature resistance, which can meet strict GMP (Good Manufacturing Practice) standards.

With the development of IoT (Internet of Things) technology, stackable plastic pallets are evolving toward intelligence. Mold manufacturers have begun to design special structures that can embed sensors and RFID (Radio Frequency Identification) chips to endow pallets with intelligent tracking functions. These innovations not only improve logistics efficiency but also bring new development opportunities to the mold industry. Kaihua Molds also keeps up with the intelligent trend and actively develops mold solutions suitable for intelligent pallets—for example, designing dedicated groove structures for sensor installation to ensure that the embedded chips do not affect pallet stacking and load-bearing, while guaranteeing the stability of sensors during long-term use. This helps customers easily achieve intelligent upgrading of pallets and seize the opportunity in logistics intelligence.

Sustainable development has become an important industry trend. Mold manufacturers are developing mold solutions more suitable for recycled material production and extending mold service life through optimized design to reduce resource consumption. The growth of leasing and pallet pool systems also reflects the industry's trend toward service-oriented transformation, which places higher requirements on mold durability and precision.

In the field of sustainable development, Kaihua Molds' advantages are further highlighted: By optimizing mold structure design, it extends the mold service life beyond the industry average, reduces mold replacement frequency, and lowers customers' equipment investment costs. At the same time, Kaihua Molds continuously improves recycled material adaptation solutions to help customers produce pallet products that meet environmental protection requirements, easily responding to the market demand for sustainable logistics carriers. The leasing and pallet pool systems have high requirements for high-frequency use and repeated stacking of pallets. However, the pallets manufactured by molds produced by Kaihua Molds, with their excellent durability and precise stacking accuracy, can adapt to the leasing scenario for a long time, providing reliable support for customers to expand their pallet service business.

The advancement of injection molding technology will continue to drive the innovative development of the stackable plastic pallet industry. With the continuous emergence of new materials and new processes, this seemingly simple logistics carrier will continue to evolve and play a more important role in improving efficiency, reducing costs, and promoting sustainable development. Relying on its rich experience in stackable plastic pallet mold manufacturing, Kaihua Molds will always continue technological innovation and customized services to provide higher-quality and more efficient mold solutions for customers in different industries, helping customers gain an advantage in the logistics efficiency competition and jointly promoting the sustainable development of the logistics industry.