Products

Products

solution and support

solution and support

contact

Contact

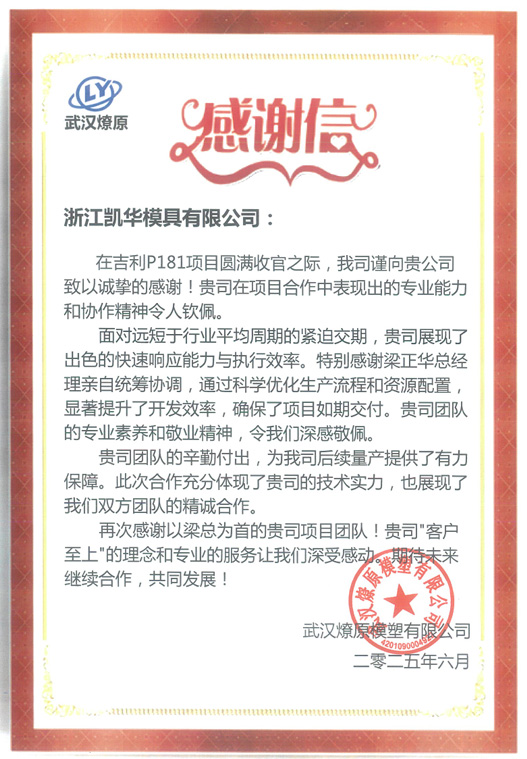

Kaihua Mold Mastery: Precision & Collaboration Redefining Speed Standards in Mold Manufacturing

TIME : 2025/6/18 14:02:26

At the critical stage of Project P181, the sudden addition of an autonomous driving version forced a complete redesign of the front bumper and related molds—with just 77 days left until mass production, far shorter than the industry’s standard development cycle. Faced with this "mission impossible," the Kaihua team, driven by their "make it possible" philosophy, joined forces with Geely’s Automotive Research Institute and Wuhan Liaoyuan’s team to launch an unprecedented industry-defying sprint.

Deep collaboration became the key to breakthrough. From day one, Kaihua and Wuhan Liaoyuan formed a joint task force, holding frequent sync-up meetings to enable real-time data sharing and swift decision-making, eliminating information silos completely. On the technical front, both sides leveraged their strengths—Kaihua contributed process optimization insights with its mold-making expertise, while Liaoyuan provided material performance support. This complementary partnership ensured seamless progress at every stage.

Strong leadership support became the project's backbone. Kaihua's top management made an unwavering commitment, with CEO Daniel Liang personally leading a dedicated task force to allocate resources and coordinate stakeholders. When technical challenges emerged, the leadership team promptly organized expert reviews to deliver professional solutions, significantly boosting team morale.

The real-time monitoring system kept full control of production pace. Project leaders worked on the shop floor daily, using their self-developed intelligent scheduling system to precisely coordinate manufacturing processes. The production line achieved seamless transitions with non-stop equipment and personnel rotation. Any potential delays triggered immediate contingency measures, ensuring smooth operations throughout the production chain.

Kaihua upholds its "do it right the first time" quality principle. Every process-from design validation to manufacturing and final inspection-adheres to rigorous standards. By implementing digital twin technology, they simulate and optimize production workflows in advance, significantly reducing lead times while maintaining uncompromised mold quality.

In the end, Kaihua successfully delivered the bumper injection molds within just 77 days - not only demonstrating their technical expertise and execution efficiency, but also securing crucial market advantages for their client. This achievement was made possible through strong partner support. Moving forward, Kaihua will further strengthen collaborations and drive innovation to achieve more breakthroughs in automotive mold manufacturing.